Abstract

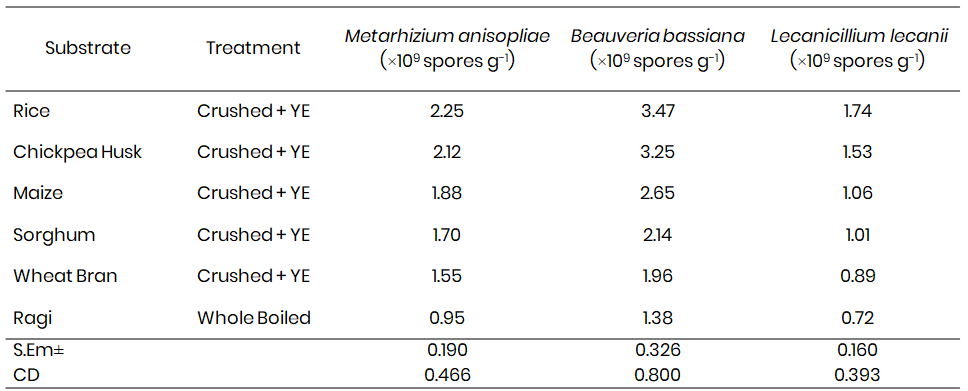

The present study was conducted to assess the biological efficacy and economic viability of six agro-industrial substrates - rice, chickpea husk, maize, sorghum, wheat bran, and ragi - for the mass production of entomopathogenic fungi Metarhizium anisopliae, Beauveria bassiana, and Lecanicillium lecanii. All substrates were evaluated under standardized treatments, and spore yields (×10⁹ spores g-1) were quantified. Among the substrates, rice and chickpea husk (both treated with crushed + yeast extract) supported the highest sporulation, with B. bassiana reaching 3.47 and 3.25 spores g-1, M. anisopliae yielding 2.25 and 2.12 spores g-1, and L. lecanii producing 1.74 and 1.53 spores g-1, respectively. These values were significantly higher (CD: 0.466, 0.800, and 0.393, respectively) than those of lower-performing substrates such as ragi, which showed minimal sporulation across all fungi. Economic evaluation indicated that chickpea husk was the most profitable substrate, with a net income of ₹ 116.50 kg-1 and the highest benefit-cost (B:C) ratio of 4.70, followed by wheat bran and rice. In contrast, ragi incurred a slight loss (₹ -0.25 kg-1), with a B:C ratio of 1.00. Overall, chickpea husk emerged as the most promising substrate for large-scale production of entomopathogenic fungi, combining high spore output with superior economic returns, making it ideal for use in microbial biopesticide development.

Introduction

The increasing concern over the environmental and health hazards associated with chemical pesticides has led to growing interest in sustainable pest management strategies. Among these, the use of entomopathogenic fungi (EPF) such as Metarhizium anisopliae, Beauveria bassiana, and Lecanicillium lecanii has emerged as an effective, eco-friendly alternative for controlling various insect pests in agriculture (Goettel and Jaronski, 2007; Jackson and Roberts, 2011). These fungi infect and kill insect hosts through cuticle penetration, ultimately leading to insect death by toxicosis and tissue degradation (Ball et al., 1994). Their effectiveness, however, depends significantly on the quality and quantity of viable spores produced, which is influenced by the substrate used during mass production (Sahayaraj and Namasivayam, 2008).

Selection of an appropriate substrate is crucial for maximizing the efficiency and cost-effectiveness of EPF production. Traditional grains like rice and maize have been widely used for fungal propagation due to their nutritional richness, but their higher costs can limit large-scale applications (Shankar et al., 2016). Agro-industrial by-products such as chickpea husk and wheat bran offer a low-cost alternative and are readily available in many agricultural regions. Studies have demonstrated that these substrates can support satisfactory conidial yields when supplemented with nutrients like yeast extract (Ranganayaki and Lakshmanan, 2020). Additionally, preparation methods, including boiling or crushing, play a vital role in enhancing the substrate’s suitability for fungal colonization and sporulation (Vimala et al., 2002).

Despite the growing research in this domain, comparative studies evaluating both the biological efficiency and economic feasibility of different substrates remain limited. Therefore, the present investigation was undertaken to evaluate six commonly available substrates - rice, chickpea husk, maize, sorghum, wheat bran, and ragi - under two different treatment methods for their ability to support spore production of M. anisopliae, B. bassiana, and L. lecanii. The study also included an economic analysis to determine the benefit-cost ratio (B:C) and net income per kilogram of production, aiming to identify a cost-effective, high-yield substrate suitable for commercial-scale fungal biopesticide production. The findings are expected to provide valuable insights for sustainable mass production strategies of EPF in integrated pest management programs.

Material and Methods

The experiment was conducted in the Department of Agricultural Microbiology, UAS, Raichur. Three fungal species - Metarhizium anisopliae, Beauveria bassiana, and Lecanicillium lecanii were procured from the microbial culture bank and maintained on SMAY (Sabouraud Maltose Agar with Yeast extract) medium.

Substrates selected for evaluation included rice, maize, sorghum, chickpea husk, and wheat bran based on their local availability and economic feasibility. Each substrate was subjected to three treatments: (1) whole boiled grains, (2) crushed grains, and (3) crushed grains with 1% yeast extract. One kilogram of each substrate was partially boiled for 5 minutes and shade dried. For treatments requiring crushing, substrates were ground coarsely. Each treatment was packed in autoclavable polyethylene bags (250 g per bag), sterilized at 121°C for 30 minutes, and inoculated with 6 mm agar discs from two-week-old fungal cultures. Bags were incubated at 25 ± 2°C and 75 ± 5% RH for 20 days. Uninoculated bags served as controls.

After incubation, fungal biomass was dried at 60°C to constant weight. Spore load was estimated by suspending 1 g of colonized substrate in 10 mL sterile water with 0.05% Tween 80, and counting was performed using a Neubauer hemocytometer. Data were analyzed using ANOVA and mean separation was done using CRD with 5% significance level.

Results and Discussion

Spore production on different substrates

The efficacy of various agro-industrial substrates in supporting the growth and sporulation of three entomopathogenic fungi Metarhizium anisopliae, Beauveria bassiana, and Lecanicillium lecanii was evaluated based on spore counts (expressed as ×109 spores g-1). The treatments involved two processing methods: Crushed + YE (yeast extract) and Whole Boiled, applied to substrates like rice, chickpea husk, maize, sorghum, wheat bran, and ragi. The spore production of fungal entomopathogens on different substrates is given in Table 1.

For Metarhizium anisopliae, rice (2.25×109 spores g-1) and chickpea husk (2.12×109 spores g-1) produced the highest spore counts. When compared with the calculated Critical Difference (CD = 0.466), the difference between rice and chickpea husk is not statistically significant, but both are significantly superior to maize (1.88), sorghum (1.70), wheat bran (1.55), and ragi (0.95), which fall below the CD threshold. Ragi, with the lowest value, was significantly inferior to all other substrates. The trend indicates that crushed substrates supplemented with yeast extract are more conducive to fungal growth than whole-boiled ones.

For Beauveria bassiana, a similar pattern was observed. Rice supported the maximum sporulation (3.47×109 spores g-1), closely followed by chickpea husk (3.25). These values are significantly higher than those for maize (2.65), sorghum (2.14), and wheat bran (1.96), when assessed against the CD of 0.800. Ragi (1.38) was again the least effective substrate and significantly different from rice, chickpea husk, and maize. These findings suggest that Beauveria bassiana sporulation is significantly influenced by substrate type, with rice and chickpea husk providing optimal nutrient profiles.

In the case of Lecanicillium lecanii, the overall spore counts were lower compared to the other two fungi. However, rice (1.74) and chickpea husk (1.53) again led the list. The CD value here is 0.393, and both these substrates are significantly superior to maize (1.06), sorghum (1.01), wheat bran (0.89), and ragi (0.72). Notably, differences among the lower-yielding substrates (maize to ragi) are not significant, as they fall within the CD range.

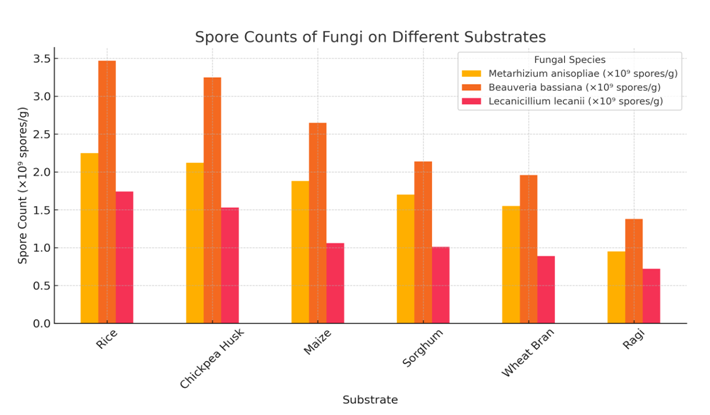

In summary, rice and chickpea husk under the Crushed + YE treatment consistently supported significantly higher spore production across all three fungal species (Fig. 1). Conversely, ragi (Whole Boiled) was the least effective substrate. The results strongly suggest that both substrate type and processing method play a critical role in optimizing entomopathogenic fungal growth for biocontrol applications.

Table 1: Spore production of fungal entomopathogens on different substrates

Fig. 1: Spore counts of entomopathogenic fungi on different substrates

Economic feasibility of substrate usage

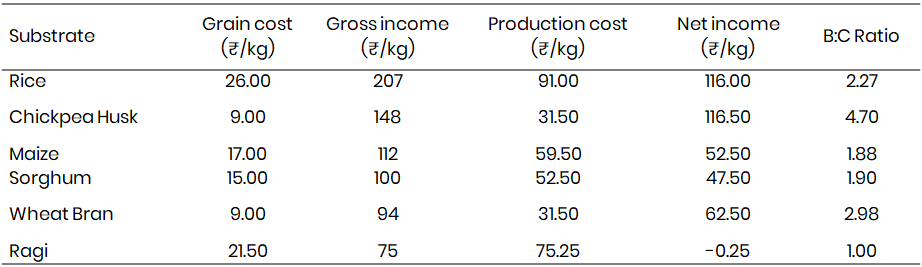

The economic feasibility of using various agro-industrial substrates for entomopathogenic fungal production was analyzed based on grain cost, gross income, production cost, net income, and the benefit-cost (B:C) ratio. The analysis revealed significant differences in profitability among the substrates and the values obtained are presented in Table 2.

Chickpea husk emerged as the most cost-effective substrate. With the lowest grain cost (₹ 9.00 kg-1) and a gross income of ₹ 148.00 kg-1, it yielded the highest net income of ₹ 116.50 kg-1 and a B:C ratio of 4.70. This reflects an excellent economic return, likely due to its low raw material and processing costs coupled with high spore productivity. The findings are in agreement with earlier reports that emphasize the value of inexpensive and nutrient-rich substrates for low-cost fungal production (Sahayaraj and Namasivayam, 2008).

Rice, though relatively expensive (₹ 26.00 kg-1), resulted in the highest gross income (₹ 207.00 kg-1) and a net income of ₹ 116.00 kg-1, closely following chickpea husk. However, due to its high input cost and higher production cost (₹ 91.00 kg-1), its B:C ratio was lower at 2.27. This still represents a viable option, especially when premium fungal quality is desired, as rice is traditionally considered a rich medium for fungal growth (Goettel and Jaronski, 2007).

Wheat bran, like chickpea husk, also had a low grain cost (Rs. 9.00 kg-1) and offered a relatively good net income of ₹ 62.50 kg-1 with a B:C ratio of 2.98, making it the third most economical choice. Maize and sorghum, though moderately priced, yielded much lower net incomes of ₹ 52.50 kg-1 and ₹ 47.50 kg-1, respectively, with B:C ratios below 2.00, indicating limited profitability.

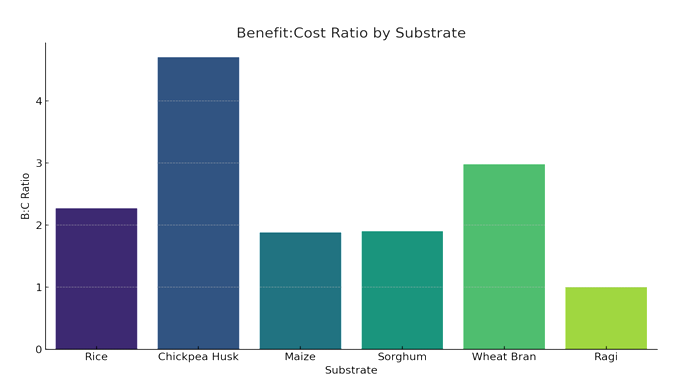

In contrast, ragi was economically unviable. Despite its mid-range cost (₹ 21.50 kg-1), the production cost (₹ 75.25 kg-1) slightly exceeded the gross income (₹ 75.00 kg-1), resulting in a negative net income (-0.25 ₹ kg-1) and a B:C ratio of 1.00, reflecting a break-even scenario. This makes ragi unsuitable for commercial-scale fungal production under the current conditions (Fig. 2).

Overall, chickpea husk and wheat bran proved to be the most profitable substrates, followed by rice. These findings support the use of locally available, low-cost agro-industrial byproducts for economical mycoinsecticide production.

Table 2: Economic analysis of substrates used for mass production of entomopathogenic fungi.

Fig. 2: Benefit cost ratio of different substrates used for fungal biopesticide production

Conclusion

The current study assessed the biological performance and economic viability of six agro-industrial substrates in supporting the mass production of entomopathogenic fungi - Metarhizium anisopliae, Beauveria bassiana, and Lecanicillium lecanii. Results demonstrated that substrate type and treatment method significantly influenced both spore yield and production economics.

Biologically, rice and chickpea husk (under Crushed + YE treatment) consistently supported higher sporulation across all three fungal species. The spore counts for these substrates exceeded the calculated critical difference (CD) thresholds, confirming statistically significant differences when compared to lower-performing substrates such as ragi and wheat bran. This highlights the importance of selecting nutrient-rich and well-processed substrates to optimize fungal biomass and spore production, as previously reported by Rombach et al. (1988) and Goettel and Jaronski (2007). Substrates like ragi, particularly when used in whole-boiled form, were found to be biologically and economically inferior.

Economically, chickpea husk stood out as the most viable substrate, offering the highest benefit-cost (B:C) ratio of 4.70 and a net income of ₹ 116.50 kg-1, owing to its low raw material cost and high biological yield. Wheat bran and rice also demonstrated favorable economics, with B:C ratios of 2.98 and 2.27, respectively. In contrast, ragi resulted in a net loss, underlining its unsuitability for commercial-scale production.

In conclusion, chickpea husk offers an ideal combination of high fungal yield and cost-effectiveness, making it the most promising substrate for mass production of entomopathogenic fungi. This integrated biological and economic evaluation provides a practical guide for selecting substrates in fungal biopesticide industries, supporting the shift toward more sustainable and affordable bio-control solutions.

References

Ball, B. V., Pye, B. J., & Carreck, N. L. (1994). Laboratory testing of a mycoinsecticide on non-target organisms: The effects of an oil formulation of Metarhizium flavoviride applied to Apis mellifera. Biocontrol Science and Technology, 4(3), 297–307. https://doi.org/10.1080/09583159409355337

Cozzi, G., Stornelli, C., Moretti, A., Logrieco, A., & Porcelli, F. (2002). Field evaluation of Fusarium larvarum formulations in the biocontrol of Saissetia oleae on olive in Apulia. Acta Horticulturae, 586, 811–814. https://doi.org/10.17660/ActaHortic.2002.586.175

Ganassi, S., Moretti, A., Stornelli, C., Fratello, B., Bonvicini, P. A., Logrieco, A., & Sabatini, M. A. (2000). Effect of Fusarium, Paecilomyces and Trichoderma formulations against aphid Schizaphis graminum. Mycopathologia, 151(3), 131–138. https://doi.org/10.1023/A:1017940604692

Goettel, M. S., & Jaronski, S. T. (2007). Safety and efficacy of insect pathogenic fungi. In L. A. Lacey (Ed.), Manual of techniques in invertebrate pathology (pp. 255–282). Academic Press.

Jackson, T. A., & Roberts, D. W. (2011). Enhancing biological control with entomopathogenic fungi: Strategies for large-scale production and field application. Biocontrol Science and Technology, 21(5), 557–571. https://doi.org/10.1080/09583157.2011.582087

Ranganayaki, R., & Lakshmanan, R. (2020). Sustainable agriculture practices using biopesticides and bio-fertilizers in India. Agricultural Science and Technology Journal, 45(3), 210–218.

Rombach, M. C., Aguda, R. M., & Shepard, B. M. (1988). Infection of Nilaparvata lugens (Homoptera: Delphacidae) by field application of Metarhizium anisopliae. Environmental Entomology, 17(4), 725–727.

Sahayaraj, K., & Namasivayam, S. K. R. (2008). Mass production of entomopathogenic fungi using agricultural products and by-products. African Journal of Biotechnology, 7(12), 1907–1910.

Shankar, M., Suneel, M., & Prasad, R. (2016). Effect of organic amendments on the growth and spore production of entomopathogenic fungi. Biological Control, 90, 87–95. https://doi.org/10.1016/j.biocontrol.2015.06.007

Vimala Devi, P. S., Prasad, Y. G., & Chowdary, A. (2002). Effect of drying and formulation of conidia on virulence of the entomofungal pathogen Nomuraea rileyi (F) Samson. Journal of Biological Control, 16(1), 43–48.

Copyright

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/