Comparative study on the effect of seed treatments and packaging types on seedling vigor and developmental traits

Abstract

A field experiment was conducted at the College of Agriculture, University of Agricultural Sciences (UAS), Bengaluru, during the rainy seasons of 2016 and 2017 to evaluate the effect of seed treatments and packaging materials on seedling growth and development in hybrid maize cultivar ‘Hema’. The study aimed to assess seedling performance after prolonged storage under various conditions. Results revealed that after a 16-month storage period, the highest mean seedling length was recorded in seeds stored in polythene bags (700 gauge) and those treated with Thiram at 2 g kg-1, measuring 27.45 cm and 27.75 cm, respectively. These were followed by super grain bags (26.75 cm) and halogen mixture treatment at 3 g kg-1 (27.25 cm), whereas the lowest seedling lengths were observed in cloth bags and untreated control (25.25 cm each). Similarly, seedling dry weight was highest in seeds stored in polythene bags (50.40 mg) and those treated with Thiram (51.83 mg), followed by super grain bags (48.35 mg) and halogen mixture (50.67 mg). The lowest seedling dry weights were observed in cloth bag storage (46.25 mg) and control (46.08 mg). The findings suggest that polythene packaging and Thiram treatment effectively preserve seed vigor and enhance seedling performance over extended storage periods in hybrid maize.

Introduction

Maize (Zea mays L.) is a globally important cereal crop, ranking third after wheat and rice in terms of production and consumption. Its remarkable adaptability to diverse agro-climatic conditions and high yield potential make it a staple crop in many parts of the world, including India, where it plays a vital role in food security and the national economy. Beyond its importance as a staple food, maize serves as a key raw material in animal feed and numerous industrial applications, including the manufacture of starch, ethanol, sweeteners, organic acids, and bio-based products.

The establishment of a healthy crop begins with the use of high-quality seed, as it directly influences seedling vigor, uniform emergence, and ultimately crop yield. In maize cultivation, ensuring optimal seed performance is particularly critical, given the crop's sensitivity to early growth conditions. Seed treatment has emerged as a vital strategy to enhance seed longevity, vigor, and resistance to both biotic and abiotic stresses during storage and germination. Harris et al. (2007) emphasized the importance of on-farm seed treatments as a cost-effective approach for smallholder farmers to improve crop establishment and productivity.

Equally significant is the role of proper seed storage. Seed viability and vigor during storage are influenced by several factors, including initial seed quality, moisture content, ambient temperature, relative humidity, seed composition, and the choice of packaging material (Doijode, 1990). Hybrid maize seeds are known to deteriorate more rapidly than open-pollinated or high-yielding varieties, often due to increased membrane damage and accelerated physiological ageing (Chen and Zhou, 1990; Rame Gowda et al., 2002). Deterioration processes begin soon after the seed reaches physiological maturity and can be exacerbated by microbial activity, which leads to the degradation of vital macromolecules such as proteins and carbohydrates.

To mitigate these effects and preserve seed quality for subsequent planting seasons, a variety of seed treatment and packaging interventions have been developed. Treatments with fungicides, insecticides, halogen compounds, and botanical extracts have shown promise in prolonging seed viability. Additionally, packaging materials such as cloth bags, polythene bags, and hermetic storage systems like super grain bags have been evaluated for their efficacy in maintaining seed integrity under prolonged storage.

Despite the existing body of work, there remains a need for comparative evaluations of the interactive effects of seed treatment chemicals and packaging types on the vigor and developmental traits of seedlings, especially under long-term storage conditions. The present study was undertaken to assess the performance of hybrid maize seeds subjected to different treatment and packaging combinations, with a focus on seedling vigor parameters such as seedling length and dry weight after extended storage.

Material and Methods

Experimental site and duration

The present investigation was carried out during the rainy seasons of 2016 and 2017 at the Department of Seed Science and Technology, College of Agriculture, University of Agricultural Sciences (UAS), Bengaluru, India. The primary objective of the study was to evaluate the effects of selected seed treatment chemicals and different packaging materials on seedling vigor and developmental traits in hybrid maize (Zea mays L. cv. Hema) under ambient storage conditions.

Seed source and pre-storage handling

Freshly harvested seeds of hybrid maize cultivar 'Hema' were obtained from a preceding field experiment. The seeds were shade-dried to attain a safe storage moisture level of 10.01%, as determined by the low constant temperature oven method, and used for subsequent storage and evaluation. Only uniform, damage-free, and viable seeds were selected for the experiment to maintain consistency across treatments.

Experimental treatments

The experiment followed a two-factor factorial design, comprising three types of packaging materials and five seed treatment options. The treatment details are as follows:

Packaging Materials (Factor P):

P1: Cloth bag

P2: Polythene bag (700 gauge thickness)

P3: Super grain bag (hermetic storage bag)

Seed Treatments (Factor T):

T1: Untreated Control

T2: Halogen mixture @ 3 g per kg of seed

T3: Sweet flag (Acorus calamus) rhizome powder @ 10 g kg-1 of seed

T4: Thiram (fungicide) @ 2 g per kg of seed

T5: Imidacloprid (insecticide) @ 3.5 g per kg of seed

The seeds were thoroughly mixed with the respective treatment chemicals to ensure uniform coating and were subsequently packed into the designated packaging materials. The treated and packed seeds were stored under ambient laboratory conditions (average temperature ranging from 23°C to 32°C and relative humidity 50–75%) for a period of sixteen months.

Experimental design and replication

The study was laid out in a completely randomized design (CRD) with a two-factor factorial arrangement and replicated thrice. The entire experiment was repeated for two consecutive years (2016 and 2017) to validate the consistency and reliability of the results across storage durations and environmental fluctuations.

Data collection

Seedling vigor traits were assessed at bimonthly intervals (every two months) over the sixteen-month storage period. For each treatment combination, 100 seeds were randomly sampled and subjected to standard germination tests as per ISTA (International Seed Testing Association) guidelines.

The following seedling growth parameters were recorded:

Seedling Length (cm): Measured from the root tip to the tip of the primary shoot for ten randomly selected normal seedlings per replicate. The average was recorded in centimeters (cm).

Seedling Dry Weight (mg): After measurement, the same seedlings were oven-dried at 80°C for 24 hours and weighed using a precision digital balance. The average dry weight per seedling was recorded in milligrams (mg).

Statistical analysis

All collected data were subjected to statistical analysis using SPSS software. Analysis of variance (ANOVA) was performed to test the significance of main and interaction effects of seed treatments and packaging materials on seedling traits. Treatment means were compared using Duncan’s Multiple Range Test (DMRT) at a 5% level of significance (p < 0.05). Graphs and tables were prepared to illustrate significant trends and treatment effects.

Results and Discussion

Initial seed quality parameters

At the commencement of the storage study, hybrid maize cultivar ‘Hema’ exhibited high initial seed quality. The seed moisture content was recorded at 10.01%, with a germination rate of 96.50%, a mean seedling length of 32.20 cm, and a seedling dry weight of 64.00 mg. No seed-borne infection was detected at the time of packaging, indicating the suitability of the seed lot for storage experimentation under controlled ambient conditions.

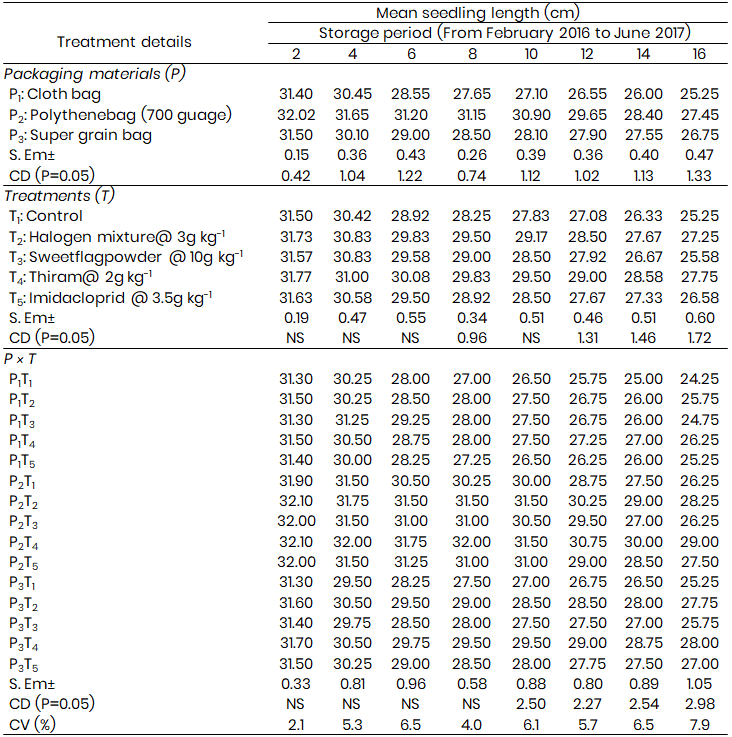

Effect on mean seedling length (cm)

The data revealed a progressive decline in mean seedling length over time, influenced significantly by both packaging materials and seed treatments, with interactions between the two becoming more evident in the later stages of storage (Table 1). Statistically significant differences were observed among the packaging materials during the 2nd to 16th months of storage (p < 0.05). At the end of the 16-month period, seeds stored in polythene bags (700 gauge) recorded the highest mean seedling length (27.45 cm), followed closely by the super grain bag (26.75 cm). In contrast, the cloth bag exhibited the lowest mean seedling length (25.25 cm), highlighting its limited capacity to maintain seed vigor over extended storage.

Among the seed treatment groups, statistically significant differences in seedling length emerged during the 8th, 12th, 14th, and 16th months. By the 16th month, seeds treated with Thiram @ 2 g kg-1 recorded the maximum mean seedling length (27.75 cm), followed by Halogen mixture @ 3 g kg-1 (27.25 cm), while untreated control seeds showed the lowest value (25.25 cm). These findings indicate the efficacy of fungicidal seed treatments in mitigating deterioration and promoting physiological integrity during prolonged storage.

Significant interaction effects between seed treatment and packaging material were evident from the 10th month onward, with the most pronounced differences observed by the end of the study. The combination of polythene bag + Thiram (P2T4) resulted in the highest mean seedling length (29.00 cm), followed closely by P2T2 (28.25 cm) and P3T4 (28.00 cm), whereas P1T1 (cloth bag + untreated) registered the lowest seedling length (24.25 cm).

The reduction in seedling length across storage durations is a classic indicator of seed deterioration, which often begins with physiological aging. This decline reflects a reduction in the mobilization and conversion of stored seed reserves into shoot and root tissues. Heterotrophic seedling growth is influenced by the seed’s initial dry matter content, the mobilizable fraction of stored reserves, and the efficiency of reserve conversion into biomass. As the storage duration increases, biochemical and structural damage - particularly to mitochondrial membranes - impairs these functions, ultimately reducing seedling elongation.

Packaging material significantly influenced seedling vigor. Polythene and hermetic bags minimized moisture fluctuations and oxidative degradation, preserving seed metabolic integrity. Cloth bags, due to their porous nature, are more susceptible to ambient humidity and pest ingress, accelerating the aging process. Similar trends in seedling length reduction with storage duration were previously documented in maize by Anil (2009), Mulla Mohammad (2012), Asha (2012), and Azad et al. (2014).

Table 1: Mean seedling length (cm) as influenced by packaging materials and seed treatments during storage of hybrid maize-Hema

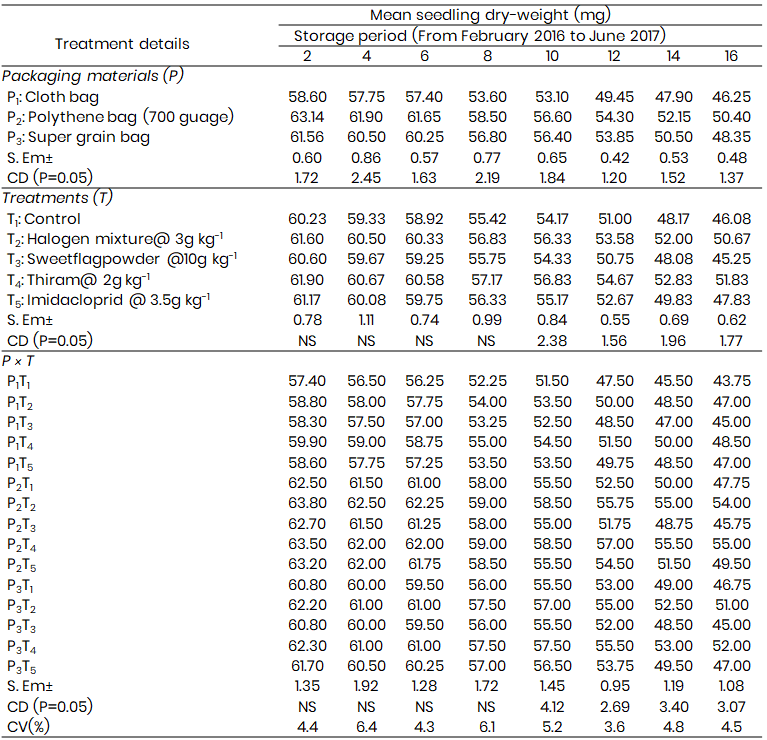

Effect on mean seedling dry weight (mg)

Mean seedling dry weight followed a trend similar to seedling length (Table 2), demonstrating significant declines with storage time, influenced by both packaging type and treatment method. Significant differences among packaging materials were observed throughout the storage period, from the 2nd to the 16th month. At the end of 16 months, polythene bags maintained the highest seedling dry weight (50.40 mg), statistically comparable to super grain bags (48.35 mg), while the lowest dry weight (46.25 mg) was recorded in cloth bag storage.

Among the seed treatments, significant variation in dry weight was evident during the 10th to 16th months. Thiram @ 2 g kg-1 again showed superior performance, with a mean dry weight of 51.83 mg, closely followed by Halogen mixture @ 3 g kg-1 (50.67 mg). The untreated control group recorded the lowest dry weight of 46.08 mg. These results reinforce the beneficial effect of fungicidal seed treatment in delaying physiological degradation and promoting seed reserve mobilization under storage stress.

Interaction effects between packaging and treatment were significant during the later storage months. The highest seedling dry weight was recorded in the P2T4 combination (55.00 mg), followed by P2T2 (54.00 mg) and P3T4 (52.00 mg). The lowest value (43.75 mg) was observed in the P1T1 (cloth bag + control) combination. The synergy of airtight packaging and effective chemical protection appeared to minimize oxidative and microbial degradation, enhancing the biochemical processes necessary for seedling tissue development.

The decline in dry weight over storage duration is attributed to reduced enzymatic activity, impaired mitochondrial respiration, and restricted mobilization of reserve compounds such as starch, protein, and lipids. Reduced metabolic efficiency during germination leads to underdeveloped shoots and roots, as observed in this study. These findings align with the earlier reports of Mahanjan (2002) in hybrid maize, Moon et al. (2011) in rice, Rahima (2008) in wheat, and Mohammad et al. (2016) in rice.

Table 2: Mean seedling dry weight (mg) as influenced by packaging materials and seed treatments during storage of hybrid maize-Hem

Conclusion

Collectively, the results affirm the critical role of both seed treatment and packaging material in preserving the physiological vigor of maize seeds over extended storage. The superior performance of Thiram-treated seeds stored in polythene or super grain bags illustrates the importance of integrating chemical and physical storage interventions for seed conservation. The deterioration pattern observed in untreated and cloth bag-stored seeds underscores the vulnerability of conventional storage methods to environmental and biological stressors.

These insights are of particular relevance to seed producers and distributors aiming to maintain hybrid seed quality across seasons and geographies. The study highlights viable strategies for enhancing seed longevity and maintaining seedling vigor, ultimately contributing to improved crop establishment and yield potential.

References

Anil Sangamathrao Hanegave. (2009). Influence of seed invigoration and polymer coating on field performance and storability of maize (Zea mays L.) (Master’s thesis, University of Agricultural Sciences, Dharwad, Karnataka, India).

Asha, A. M. (2012). Effect of plant products and containers on storage potential of maize hybrid cv. Arjun (Master’s thesis, University of Agricultural Sciences, Dharwad, Karnataka, India).

Azad, A. W., Joshi, J., Anurag, T., & Tomar, D. S. (2014). Effect of seed treatments and packing materials on seed quality parameters of maize (Zea mays L.) during storage. Indian Journal of Applied Research, 4, 40–44.

Chen, L. B., & Zhou, G. Q. (1990). Correlation between permeability of membranes and germination of rice seeds. Plant Physiology Communications, 5, 36–38.

Doijode, S. D. (1990). The influence of storage containers on germination of onion seeds. Maharashtra Agricultural University Journal, 15, 34–35.

Copyright

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/